Robust, Easy to Use Controller Designs

The new controller designs (Boost Dependent Kit PN 30-3300 & Multi Input Kit PN 30-3350) feature large, turn-resistant knobs and larger numbering to easily set accurate start and full activation points, with covered status LED and test buttons for added splash resistance. A plug is integrated into the controller housing for mating to the redesigned wiring harness’s positive-lock connector. The Boost Dependent controller housing has a molded-in, barbed nipple to accept a boost hose and a wiring legend on the back. Both controller housings feature an easy to access integrated fuse and molded mounting tabs.

Innovative Injector Design Delivers Faster Cooling with Less Fluid Used

Our breakthrough injector design uses unique Swirl Generator Technology that improves atomization to deliver faster inlet temp cooling and uses less fluid to maintain inlet air cooling. We include three Swirl Generators that deliver 250cc, 500cc, and 1000cc of flow. The AEM V3 WMI injector is included in every AEM Water/Methanol injection kit and is a direct replacement/upgrade for the V2 injector in older systems (V3 Injector PN 30-3315).

In testing at AEM, the new V3 250cc WMI nozzle and the V2 250cc WMI nozzle both achieved a 90-degree inlet temp reduction; however, the V3 nozzle design achieved this reduction nearly 6.5 seconds faster. Consider that on an average sportsman drag car this can represent close to 40% of track time. On a road race car, applying more timing 6.5 seconds faster can mean a critical time to pass on a corner exit.

We then tested a V3 250cc injector against a V2 500cc injector to see if the larger V2 injector would improve cooling speed. The V2 500cc injector achieved nearly identical cooling speed as the V3 250cc injector, but it required almost 44% more fluid to achieve the same cooling. Less fluid used means fewer refills of your WMI tank and less money spent refilling it. Using the V2 500cc nozzle with a one-gallon tank, you will get close to 7 minutes and 50 seconds of run time at full pressure. Using the V3 250cc nozzle with a one-gallon tank, you will get 13 minutes and 30 seconds of run time at full pressure.

Click the link for a Nozzle Flow Guide graph.

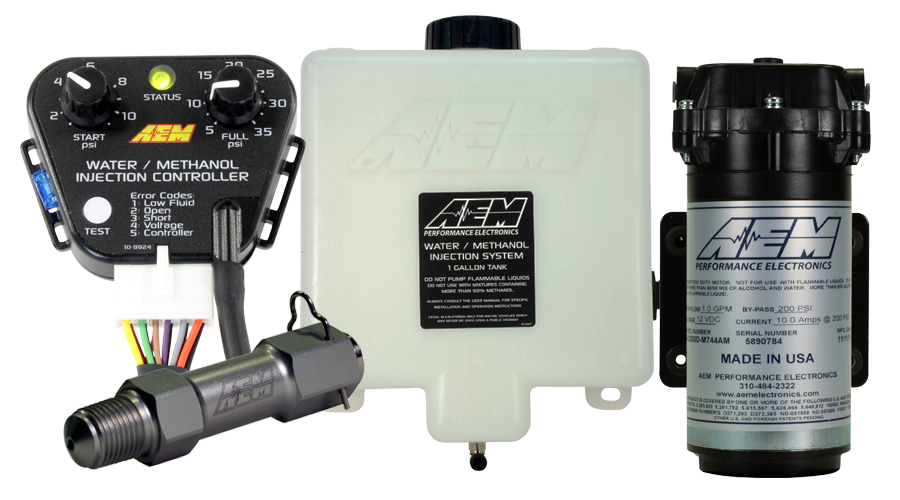

Heavy-Duty Waterproof High Pressure Injection Pump – Safe for Engine Bay/Frame Rail Mounting

AEM’s internally-bypassed water/methanol injection pump is waterproof and safe for mounting in loactions that are exposed the elements. It does not cycle on and off and provides quiet, smooth operation. It features robust construction including integral hose fittings, EPDM seals and a Santoprene diaphragm that provides consistent and reliable fluid delivery.

Low-Profile 1.15 Gallon Tank

AEM’s gas Water/Methanol Injection Systems are available with or without a compact 1.15 gallon tank that features an anti-starvation reservoir. A more accurate, conductive low level fluid sensor is integrated into the tank and features a positive lock connector with color-matched wires to the wiring harness. The sensor eliminates any chance of incorrect readings due to interference from debris.

Simplified Wiring

AEM’s Water/Methanol Injection kit’s wiring harness is terminated with a positive-lock connector on one end and has color-coded wires to ease installation. Both the power and ground wires for the pump are included in the harness which simplifies the wiring process and eliminates any chance of the pump accidentally activating from a short in the system. An additional wire is included for adding an optional on/off solenoid to stop fluid flow when the system is inactive.

Integrated Boost Safe Feature

The controllers in AEM’s Water Methanol systems include an integrated “Boost Safe” output feature that monitors the entire injection system and triggers a ground signal via an output if it detects a voltage-related error (short, bad connection, broken wire, overheated pump, high or low voltage signal, etc.), allowing users to define their failsafe strategy from something as simple as flashing a warning light to more advanced strategies like pulling boost or ignition or switching fuel maps on a standalone engine management system. Combined with the integral and highly accurate conductive low-fluid switch in the tank, “Boost Safe” can also put your engine in safe mode before the system runs dry. This exclusive feature is found only on AEM Water/Methanol Injection Systems.

Revised Flow Control Strategy for More Linear Fluid Delivery

AEM’s engineers spent extensive time revamping the controller’s flow control strategy for a more linear flow output delivery. This means that the flow delivery better matches an engine’s need for water/methanol injection, which further optimizes charge air cooling and detonation control.

- Boost Dependent and Multi-Input (0-5v/frequency) progressive controller designs feature large adjustment knobs, integrated plug for harness connection, integrated fuse, covered status light and test button for enhanced splash resistance and mounting tabs

- Wiring harness is terminated with a positive-lock connector on one end with color-coded wires to ease installation, integrated pump ground circuit and additional wire for optional on/off fluid solenoid

- “Boost Safe” failsafe output included (for complete failsafe under all conditions, see our Water/Methanol Failsafe Device)

- Heavy-duty high-pressure injection pump features integral fittings, a Santoprene diaphragm and EPDM seals to resist corrosion. Our pump maximizes line pressure for optimum atomization and its quiet, smooth operation is almost undetectable

- Precision-machined billet-aluminum injector with integral check valve

- Three interchangeable injector nozzles to cover a wide variety of HP levels (250cc/min, 500 cc/min & 1,000cc/min)

- 1.15-gallon tank with anti-starvation reservoir, integral conductive low-fluid sensor and positive lock connector (tank-less systems available)

- 20 feet of injection tubing included

- LED dash light for system status and low fluid warning

WATER/METHANOL INJECTION ADVANTAGES FOR GAS ENGINES:

Reduces Air Inlet Charge Temps

The term “liquid intercooling” with water/methanol injection refers to a highly atomized mist of water/methanol that is injected into the airstream and begins to evaporate. As it does, this evaporative effect reduces air charge temps by as much as 100 degrees, and delivers a more oxygen-rich air charge.

Reduces Detonation (Knock)

Water absorbs heat, and methanol is a cool burning, anti-knock rated fuel. When combined and introduced into the inlet stream, they can effectively increase your vehicle’s anti-knock index so you can reliably increase boost pressure and advance ignition timing using pump gas.

Reduces Carbon Deposits

Modern vehicles fitted with Exhaust Gas Recirculation (EGR) devices for emissions control promote heavy carbon build up inside the air intake. This carbon build-up can create ‘hot spots’ in the combustion chambers that can cause detonation. Water/methanol injection has a ‘steam cleaning’ effect that reduces this carbon build up, and in some cases can increase fuel economy.

Reviews

There are no reviews yet.